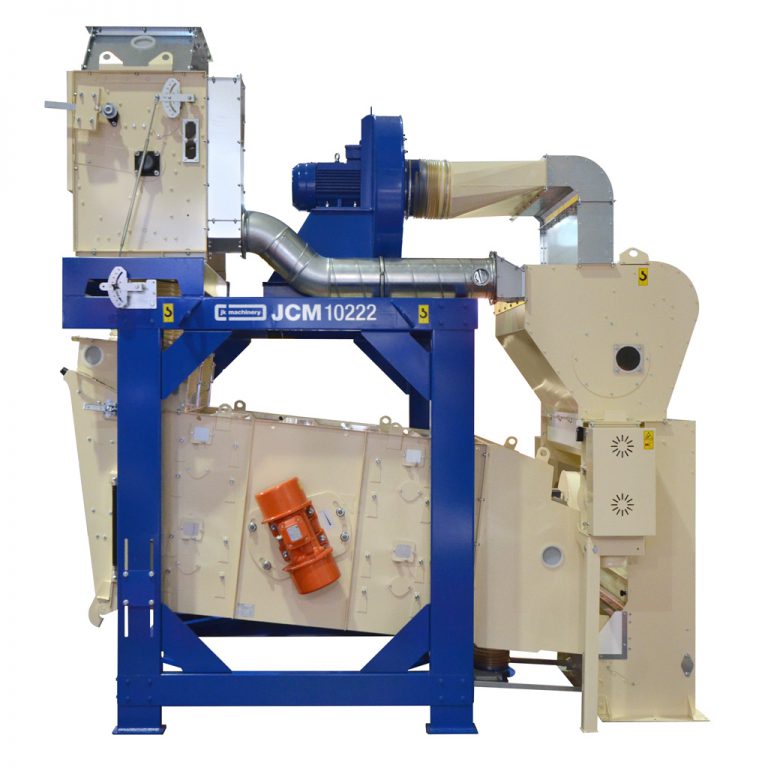

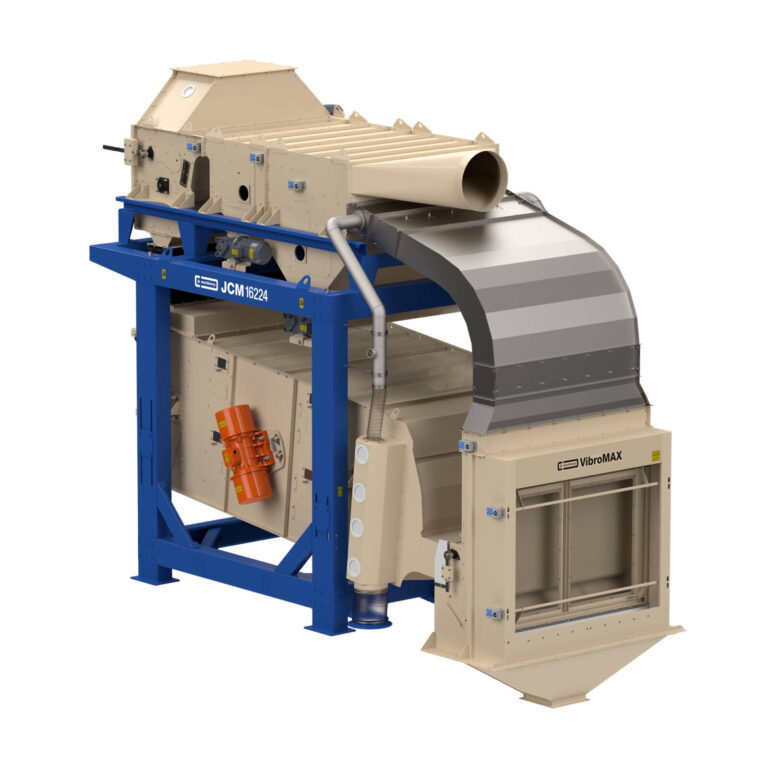

JCM Modular Cleaners VibroMAX are designed to clean all agricultural crops from impurities and admixtures. The product is separated based on different particle sizes (sieves cleaning) and different aerodynamic properties (air cleaning).

JCM Cleaners are designed for continuous operation or for greater performance. Sieves are cleaned by rubber balls. Vibrations of sieve box are produced by pair of vibromotors.

Adjacent aspiration channel provides separation of small impurities. Controllable wall of aspiration channel provides for optimal shape adjustment of air channel. Aspiration channel has a built-in permanent magnet that provides separation of ferromagnetic impurities. Machines box construction and air recirculation drain dust into designated areas.

Cleaner and aspiration channel set can be optionally completed with extra modules. For inlet aspiration of machine can be added P1 module: JAC – aspiration precleaner without rotary feeder, or P2 module: JAM – aspiration precleaner with rotary feeder, for some models also P3 module: JAN – aspiration precleaner with rotary feeder and expansion separator. Standard solution of machine outlet aspiraton is ensured by A2 module: JAB – aspiration channel with adjustable channel, or it can be replaced with A3 module: JAE – aspiration channel with adjustable channel and expansion chamber.

| Machine type JCM | 08122 | 08123 | 10122 | 10123 | 10222 | 10223 | 16224 | 08133 | 10133 | 10143 | 10413 | |

| PERFORMANCE | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pre-Cleaning | t/h | 20 | 30 | 50 | 60 | 80 | 100 | 200 | - | - | - | - |

| Industrial Cleaning | t/h | 12 | 18 | 25 | 40 | 50 | 80 | 100 | - | - | - | - |

| Fine Cleaning | t/h | 6 | 9 | 12 | 18 | 25 | 35 | 50 | 6 | 8 | 10 | 50 |

| DIMENSIONS: | ||||||||||||

| Length | mm | 2220 | 2860 | 2800 | 3650 | 3100 | 3920 | 4740 | 2950 | 3870 | 3470 | 3940 |

| Width | mm | 1320 | 1320 | 1650 | 1650 | 1650 | 1650 | 2650 | 1350 | 1650 | 1650 | 1650 |

| Height | mm | 1460 | 1610 | 1735 | 1860 | 2240 | 2390 | 3830 | 1770 | 2060 | 2390 | 2390 |

| OTHERS: | ||||||||||||

| Rough sieve area | m² | 1,9 | 2,8 | 3,4 | 5,1 | 6,7 | 10,1 | 15,1 | 4,3 | 7,6 | 10,1 | 10,1 |

| Weight | kg | 620 | 680 | 950 | 1070 | 1270 | 1520 | 2700 | 800 | 1360 | 1550 | 1210 |

| NOTE | ||||||||||||

| Capacities are valid for wheat cleaning, bulk density 750 kg/m3, humidity max. 16% and when using wire sieves. Machine capacity for each crops types is changing by humidity and the degree of inpurities content, on quality settings and machine adjustements. Dimensions and weights are mentioned incl. aspiration channel (version C1P0A2). | ||||||||||||